An Economic Assessment of China’s Rare Earth Policy

Publication: China Brief Volume: 10 Issue: 22

By:

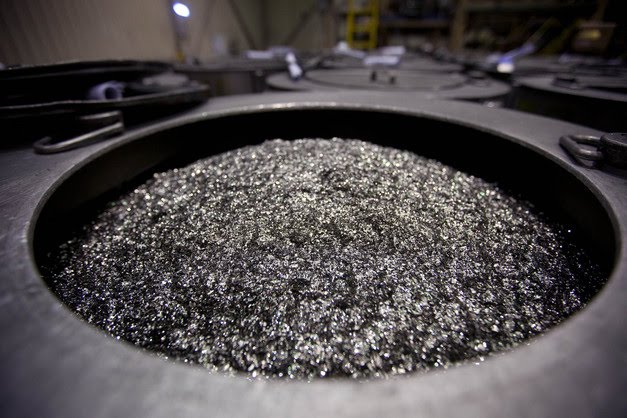

The term rare earths (RE) apply to a group of 17 chemically similar metal elements that include scandium, yttrium and the fifteen lanthanides. RE elements are considered strategically important commodities that are used to manufacture defense and commercial high value-added applications, especially green technology. Rare earths were traded freely and at a discounted price on the global market before the mid-2000s. Since 2005, however, China—the world’s leading RE producer—gradually tightened export restrictions on rare earth oxide (REO). In late September, Chinese exports of REs to Japan were reportedly halted due to a dispute over maritime boundaries in the East China Sea, which underscored an unprecedented risk in the global RE supply chain. Most consuming countries were caught unprepared by this RE supply crisis. Indeed, China’s annual REO output at 129,405 tons in 2009 represents 97 percent of world total, and the technological complexity, resource availability and capital intensity of RE separation and processing make the diversification of supply away from China implausible in the near term.

Figure 1: Chinese Rare Earth Industry in the International Context [1] (available in PDF)

Drivers Underlying China’s Ascendance

China’s dominance in the RE supply chain is directly related to Beijing’s consistent and long term planning, which dates back to as early as the 1950s. Nevertheless, the Chinese RE industry did not take off until Xu Guangxian (also known as "The Father of Chinese Rare Earths Chemistry") developed the Theory of Countercurrent Extraction—which is applicable for the separation of a mixture with more than ten components such as rare earths—in the 1970s. Since then, China’s REO output has increased rapidly from slightly over 1,000 tons in 1978 to 11,860 tons in 1986, which marks the year when a production spike at the giant Bayan-obo mine first propelled China past the United States as the world’s leading producer of REO. Meanwhile, Beijing has continuously invested heavily in technological innovations through key national R&D programs, such as the 863 and 973 projects, in order to gain a decisive advantage in the rare earth supply chain including mining, separation, refining, forming and manufacturing [2]. Not coincidentally, after the late Chinese patriarch Deng Xiaoping famously stated, “the Middle East has oil, and China has rare earths” in 1992, China has not only remained the world’s largest REO producer, but has also successfully moved its manufacturers up the supply chain. Since 1990, domestic consumption of REO for high value-added product manufacturing in China has increased at 13 percent annually, reaching 73,000 tons in 2009 [3].

The significant cost advantage for Chinese producers, which has crushed almost all overseas competitors, is not only driven by low labor costs, but also unintentionally reinforced by Beijing’s policy failures in regulating the resource extraction sector as a whole, and the RE industry in particular. To keep pace with its booming economy, Beijing promulgated the so-called “Let Water Flow Rapidly” (You Shui Kuai Liu) policy in 1981 to stimulate no holds-barred mining developments to meet a rapid spike in resource demand without appropriate considerations of environmental protection, safety and sector consolidation. The lack of entrance standards and patent enforcement led to a proliferation of small scale and technologically backward mines and separation plants. By 2008, more than 100 enterprises held 123 RE mining permits in China, and China’s combined REO production capacity had exceeded 200 kt/annum, which is significantly higher than the global demand at 134 kt (Nanfang Metropolis News, September 8). Widespread and chronic illegal mining operations further aggravated the situation. In 2008, the reported REO output in the southern province of Guangdong was only 2,553 tons, but an investigation by the Ministry of Industry and Information Technology (MIIT) indicated that the actual output level was 25 to 30 kt [4]. While REO output was seriously underreported, overcapacity in China was becoming a detrimental factor that eventually destabilized the global RE market. Not surprisingly, hundreds of Chinese RE exporters competed furiously with each other in the export market, leading to more than a 60 percent drop on the average REO price between 1992 and 2006 [5].

The Chinese RE industry could not have attained its current monopoly status without, in part, the strategic miscalculation of the United States and the vulnerability of Japan due to the latter’s absence of upstream RE resource endowment. Through the 1960s until the 1980s, the Mountain Pass mine in California was the leading RE producer in the world. Burdened with both the cutthroat price competition from Chinese exporters and California’s stringent environmental laws, Mountain Pass ceased operations without state intervention in the early 2000s. Moreover, since 1990, a significant portion of manufacturing operations employing REs in the United States has been sent offshore to Asia. Not surprisingly, the United States is losing its longstanding leadership in many areas of RE technology [6]. In comparison, as the leading economy in use of REs for advanced electronics and green techniques, Japan has bided its time by building an unspecified amount of RE stockpiles. Nevertheless, Japan’s absence of domestic resources precluded supply diversification as a viable economic option during the era of cheap Chinese RE exports.

Strategic Considerations and Implications

Relying on upstream RE resources to gain access to advanced techniques and encourage high value-added downstream operations has long been a national policy in China that dates back to as early as the 1970s. After China gained decisive advantage in the RE supply chain, Beijing’s restrictions on REO production and exports in recent years have been primarily motivated by the strong political desire for resource conservation. Though China’s proven RE reserves of 52 Mt represents 45 percent of world total, these valuable resource endowments are not evenly distributed. The majority of China’s proven RE reserves, including Bayan-obo mine in Inner Mongolia (with proven reserves at 43.5 Mt), Liangshan mine in Sichuan (1.5 Mt) and Weishan mine in Shandong (4.0 Mt), contain only light REs. In comparison, while most of the global supply of heavy REs (e.g. yttrium) originates in the "ion adsorption clay" ores of Southern China, the proven reserves of heavy REs in the 7 Southern Chinese provinces are a mere 1.5 Mt [7]. Since heavy REs are considered more strategically valuable, significant efforts have been made by Beijing in recent years to crack down rampant illegal mining in Southern China. Though the United States may regret the closure of Mountain Pass in the early 2000s, the Chinese decision makers and academia actually perceive the above event from a different angle: the United States holds valuable resources as strategic stockpiles by taking advantage of cheap and environmentally destructive REs from China (China Daily, October 26).

Beijing has been wary of the stockpiling of REs outside China. Though a senior Japanese official stated that Japan’s stockpile of REs could dry up by next March or April without fresh imports from China, a claim that has been widely quoted by the Chinese media is that Japan actually only consumed one third of its RE imports in the past and thus has successfully built up strategic stockpiles which can last the country for 20 to 50 years (Beijing Business Today, October 28; The Sydney Morning Herald, October 22; Wen Wei Po, October 10). As Beijing well understands the negative impacts of overseas stockpiles on the strength of its RE industry, it has sharply lowered its annual REO export quote from 65,609 tons in 2005 to 30,258 tons in 2010 [8]. According to the revised “2009 to 2015 Development Plan of the Rare Earth Industry” prepared by the MIIT, the annual REO export level from China will be restricted below 35 kt between 2009 and 2015. In addition, China will only produce 130 to 150 kt of REO annually (21st Century Business Herald, August 15; Financial Times, October 24). If the aforementioned targets can be strictly enforced, the existing stockpiles outside China are expected to be exhausted over time, which will further strengthen China’s competitiveness.

Contrary to the backfiring theory claimed by some observers (Reuters, October 28; China Economic Review, September 28), the lack of overseas RE producers does not necessarily serve Beijing’s strategic interests. Of all the 16 naturally occurring RE elements at commercial scale (there are no stable or long-lived isotopes of promethium), the cost competitiveness of the Chinese RE industry is unlikely to be undermined by any potential competitor in the near future. According to data from Shanghai Metal Market online, prices of neodymium oxide and dysprosium oxide have increased by 80 percent and 125 percent between January and September 6. Nevertheless, Xu Guangxian still expressed dissatisfaction with these terms. During an interview given to a Chinese-magazine, Xu said, “production costs by overseas producers are 400 percent higher than China’s REO export prices. As a result, market prices of REO should increase by at least 400 percent. Because of resource scarcity, price of dysprosium oxide should show a tenfold growth in the future” (Talents, September 30).

Numerous large RE deposits exist outside China, and the long-term sustainability of the Chinese monopoly is questionable at best. Nevertheless, the global diversification of supply away from China may not improve the current situation as expected. Following the recent Chinese RE embargo, Toyota responded quickly with a plan to team up with Sojitz and the Vietnamese government to mine REs at Dong Pao (5 kt/annum). Sumitomo, the Japanese trading house, has struck a deal with Kazatomprom, Kazakhstan’s state nuclear power company, in a bid to secure supplies of RE metals (3 kt/annum). Moreover, Japan has reached an agreement with Mongolia to promote development of RE projects. Similarly, RE development has been initiated by Molycorp at Mountain Pass (10-20 kt/annum), Lynas at Mount Weld (10-20 kt/annum), Afrafura Resources at Nolans (10 kt/annum), Avalon Rare Metals at Nechalacho (5 kt/annum), Great Western Minerals Group at Hoidas Lake (3-5 kt/annum), Rare Element Resources at Bear Lodge (13.6 Mt of REO resources), Greenland Minerals and Energy at Kvanefjeld (4.91 Mt of REO resources) and Neo and Mitsubishi at Pitinga (xenotime concentrate from Tin tailings) [9]. Yet, few questioned whether consuming countries such as Japan or companies like Toyota are willing to share such valuable resources with their economic competitors. Moreover, some RE elements are just too scarce to be completely subject to free trade. For instance, outputs of both metal dysprosium and terbium in China are below 40 tons per year [10]. While Beijing started to guard such scarce resources carefully, any new entrant is likely to follow suit. As a result, even if sizable RE production capacity is materialized outside China in the future, free trade of all REs without restriction is still unlikely. To make the matter worse, given China’s decisive cost advantage, Beijing could easily exert control on RE pricing to squeeze out new competitors in the future.

The dominance of the Chinese RE industry may seem formidable, but Beijing’s control of this industry is actually not as tight as many outside observers believe. The Chinese adage applies: There exist too many places in China where “the mountains are high, and the emperor in Beijing is far away.” Based on REO supply and demand balances in China and the outside world, the author estimates that about 20 to 40 kt of REO have been either smuggled outside China or held at unknown stockpiles on an annual basis in recent years [11]. With spiking prices of REs in the international market, the economic incentives of RE smuggling become even more difficult to resist for those with access to RE resources within China. Finally, while Beijing plans to drastically consolidate its RE industry and reduce the number of RE separation plants from around 100 to 20 by 2015, the local governments are battling furiously for the control of their indigenous resources.

The ascendance of the Chinese RE supply chain is the outgrowth of Beijing’s long-term planning, the invisible hand of the free market and, as this paper has shown, strategic miscalculation made by the U.S. government. Though sizable RE production capacity may be developed outside China, Beijing is expected to remain the leading producer with the formidable power to squeeze out any new competitor, thus China is able to continuously reserve the right to use REs as a political bargaining chip in the years to come—in spite of what its leaders claim (Xinhua News Agency, October 28). Nevertheless, Beijing’s current RE policy will not only face challenges from the international community, but it will also need to overcome the autonomous and often chaotic nature of the Chinese economy and the conflict of interests between the central and local governments. Even so, given the strategic importance of RE resources, new overseas entrants may soon follow suit with behavior similar to China’s. As a result, the era of cheap Chinese rare earths may be forever gone.

Notes

1. USGS / Rare Earth Information (various issues) / Non-ferrous Mining and Metallurgy, vol. 1996(4) / Economic Analysis of Metallurgy, vol.1989(4) / and etc.

2. Cindy Hurst, China’s Rare Earth Elements Industry: What Can the West Learn? IAGS: Fort Leavenworth (2010).

3. Song and Hong, Status and Forecast of the Chinese Rare Earth Industry. Rare Earth Information, vol.2010(1) (2010); Industrial Source.

4. R. Li, Dilemma of Rare Earth Resource Consolidation. China Metal Bulletin, vol.2010(8) (2010).

5. Price data from USGS.

6. Fifarek and et al., Offshoring Technology Innovation: A Case Study of Rare-earth Technology. Journal of Operations Management, vol. 2008(26) (2008).

7. Hutai United Securities, Summary on the Field Trip to Investigate the Rare Earth Industry in Jiangxi (2010).

8. Source: Ministry of Commerce, Ministry of Land and Resources.

9. Rising Securities, Beauty of Rear Earths: Rationally Understand the Sector Development (2010); Japan Today, October 3 and 23; https://www.ggg.gl and https://www.rareelementresources.com.

10. Industrial source.

11. USGS / Rare Earth Information (various issues); and etc.