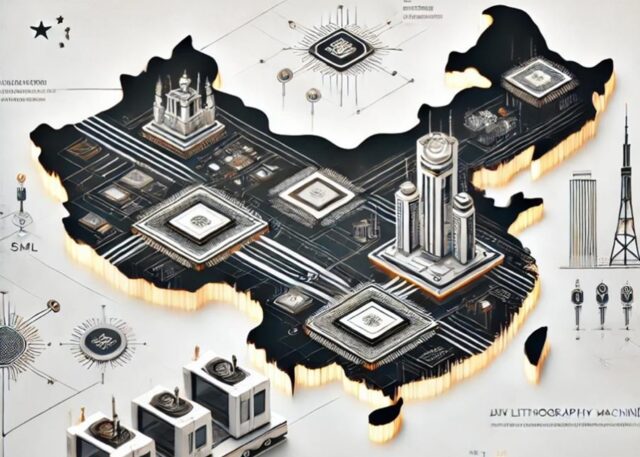

MIIT Overhypes Lithography Breakthrough

By:

Executive Summary:

- The People’s Republic of China (PRC) has announced breakthroughs in semiconductor manufacturing, specifically in Deep Ultraviolet (DUV) lithography, as part of its effort to achieve technological self-sufficiency amid US sanctions.

- The DUV machines showcased by the Ministry of Industry and Information Technology (MIIT) still lag significantly behind global leaders like ASML, especially in terms of overlay precision and the ability to produce advanced chips.

- Practical challenges persist in the PRC’s adoption and refining of DUV and Extreme Ultraviolet (EUV) lithography at scale. Low yield rates and high production costs due to having to rely on technological workarounds remain an obstacle.

In recent announcements, the Ministry of Industry and Information Technology (MIIT) has claimed that advances in deep ultraviolet (DUV) lithography constitute a breakthrough in the People’s Republic of China’s (PRC) push toward semiconductor independence. If true, these developments would suggest that the PRC is achieving some success in its push for greater self-reliance amid increasing US sanctions that have restricted its access to certain advanced technologies. A closer examination of the claims reveals a more nuanced narrative than MIIT’s statements imply.

Assessing MIIT’s Claims on Lithography Machines

MIIT has announced advancements in DUV lithography technology, which is used to make chips (MIIT, September 2). The breakthroughs are in Krypton Fluoride (KrF) and Argon Fluoride (ArF) systems, which are essential for transferring microelectronic patterns onto silicon wafers. These technologies are vital in producing features suitable for various applications, but DUV machines remain inferior to extreme ultraviolet (EUV) machines, which is used to create the most advanced chips currently in production as it enables even more microscopic feature sizes. DUV is nevertheless crucial to the PRC’s overall semiconductor ambitions, and advances to KrF and ArF machines are notable (Cymer, accessed September 16; ASML, accessed September 16).

Developments in the PRC’s DUV lithography technology have received a fair amount of publicity. Focus has been on the “potential” to produce 8nm chips, as the overlay (套刻) precision of these machines—a measure of how accurately different layers of a circuit align during manufacturing—does not necessarily correlate with the actual feature size achievable on the chips. Media reports have conflated overlay precision with the ability to produce smaller, more advanced chips (163, September 15; TrendForce, September 16; RFA, September 16). This is not necessarily the case, however (SemiEngingeering, November 16, 2017). Consequently, this misunderstanding has fueled exaggerated claims about the PRC’s semiconductor progress.

There remains a significant technological gap with the world leaders in this area. For instance, ASML’s TWINSCAN XT: 1460K, released in 2015, boasts an overlay precision of less than 5nm. The DUV machines listed by MIIT feature resolutions similar to ASML’s TWINSCAN XT: 1460K, but have a vastly inferior overlay precision (ASML, accessed September 16). Another ASML DUV model, the TWINSCAN XT:1450, achieved resolution of 57nm and overlay precision of 7nm back in 2006 (ASML, December 6, 2006). On this metric, the PRC is 18 years behind the cutting edge.

Challenges and Ambitions in China’s Lithography

There are ways in which the PRC has been able to innovate to produce more advanced chips despite using less developed lithography machines. Many chip manufacturers in the PRC have adopted technologies like ASML’s immersion lithography, which uses multi-patterning technology to expose simpler, interlaced patterns multiple times to create complex layers (ASML, August 2, 2023). This approach allows for finer feature creation, but it also increases production costs and lowers yields, particularly as overlay precision becomes more critical for further miniaturization (Baidu, September 15; ASML, August 2, 2023). For instance, Semiconductor Manufacturing International Corporation (SMIC), one of the PRC’s leading semiconductor companies, has reportedly achieved only a 15 percent yield rate for its 7-nm process using non-EUV way, inflating the cost of these chips to nearly ten times that of similar chips produced by TSMC (ETN, August 23, 2022).

On a parallel front, Shanghai Micro Electronics Equipment (SMEE) recently filed a patent for “Extreme Ultraviolet Radiation Generator and Lithography Equipment,” suggesting ambitions to crack EUV lithography, technology that the PRC has had difficulty acquiring due to export restrictions (Stock, September 12). (SMEE is currently on the US Department of Commerce’s Entity List (ECFR, accessed September 24)). SMEE’s system allegedly includes a chamber that houses a target material generator and a laser generator. The laser is used to emit light towards the target material, producing charged particles and extreme ultraviolet light. As the patent has just been filed, its viability in practice and its potential as a competitive global product remains unclear.

Conclusion

The PRC continues to make strides in developing its domestic semiconductor technology. Technical challenges remain, however. Stakeholders should not be swayed by bold claims without considering the complexity of an industry where precision and reliability are paramount. Caution is always necessary when evaluating PRC’s official announcements, and particularly when those relate to technological advances.